GOLDFLEX 608L – 610L

Automatic carton formers

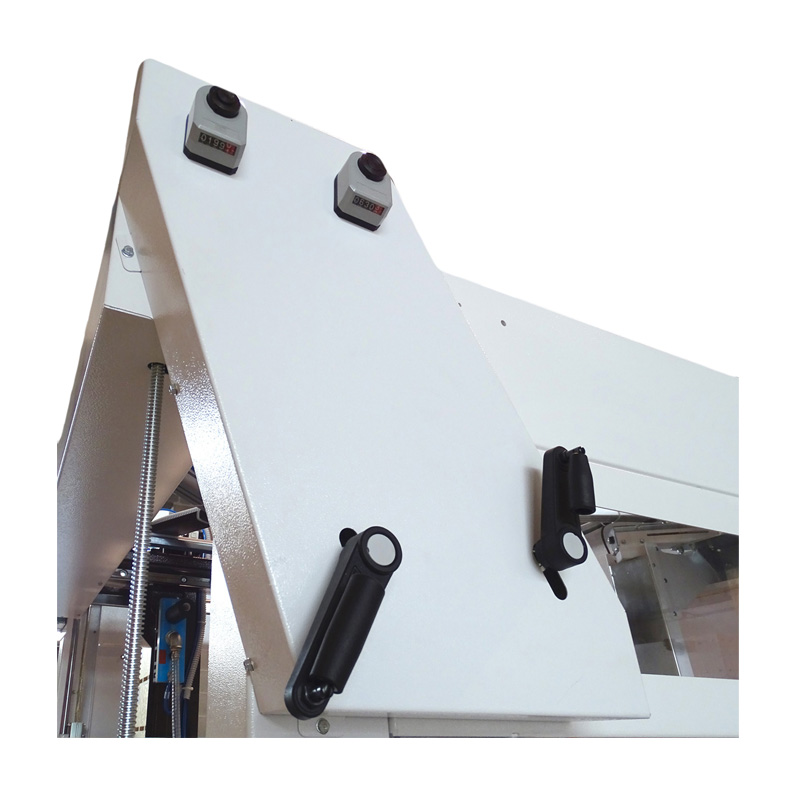

The machine automatically forms large American-type boxes and folds the bottom four flaps. The machine must be adjusted through handles with position indicators on the box dimensions to be formed. The folding system of the bottom flaps is ensured by the perfect synchronization of the movements of the levers.The suction cup system, operated by a Venturi unit, picks up the cartons from the magazine and supports them during the opening function. After forming, the folded bottom flaps can be taped, with the GT65B bottom taping machine, or sealed with Hot-Melt glue with the GT65B-HM; the box is then conveyed to a filling station, either manual or automatic, and then taped or glued at the top by means of special machines down the line.

equipped with standard 1.3m motorized magazine box capacity about 120/130 depending on thickness

Siemens S7 1200 PLC

Safety guards and clear methacrylate doors equipped with uniquely coded RFID security micro for immediate stop in case of opening

Gripping head with suction cups operated by Venturi vacuum system

Ergonomic layout of the control panel

TECHNICAL DATA

GF608L |

||

| TECHNICAL DATA | U.M. | |

| Machine footprint (LxWxH) | mm. | 2082x2930x2212 |

| Machine weight | Kg. | 950 |

| Hourly production rate | Boxes/h | 400 ÷ 450 |

| Warehouse capacity (MAG 681) | No. of boxes | 130 |

| Workbench height | mm. | 725 |

| ELECTRICAL CHARACTERISTICS | U.M. | |

| Supply voltage | V | 400 |

| Line phases | n° | 3~+PE |

| Power frequency | Hz | 50 |

| Installed power | kW | 0,5 |

| Electrical protection level | IP | 54 |

| PNEUMATIC DATA | U.M. | |

| Air consumption per cycle | Nl/cycle | 24 |

| Operating pressure | bar | 6 |

| Vacuum unit (Venturi) | m3/h | 22 |

| Vacuum unit (Venturi) | mmHg | 680 |

| BOX FEATURES | U.M. | |

| Minimum dimensions of boxes with open top flap (LxWxH) | mm. | 350x150x295 |

| Maximum dimensions of boxes with open top flap (LxWxH) | mm. | 800x650x975 |

| Box Type (suitable in an automatic process) | ref. FEFCO | 0200 / 0201 |

| Grooves (corrugation) type | ref. GIFCO | A-B-C |

GF610L |

||

| TECHNICAL DATA | U.M. | |

| Machine footprint (LxWxH) | mm. | 2282x2930x2212 |

| Machine weight | Kg. | 980 |

| Hourly production rate | Boxes/h | 400 ÷ 450 |

| Warehouse capacity (MAG 610) | No. of boxes | 130 |

| Workbench height | mm. | 725 |

| ELECTRICAL CHARACTERISTICS | U.M. | |

| Supply voltage | V | 400 |

| Line phases | n° | 3~+PE |

| Power frequency | Hz | 50 |

| Installed power | kW | 0,5 |

| Electrical protection level | IP | 54 |

| PNEUMATIC DATA | U.M. | |

| Air consumption per cycle | Nl/cycle | 24 |

| Operating pressure | bar | 6 |

| Vacuum unit (Venturi) | m3/h | 22 |

| Vacuum unit (Venturi) | mmHg | 680 |

| BOX FEATURES | U.M. | |

| Minimum dimensions of boxes with open top flap (LxWxH) | mm. | 350x150x295 |

| Maximum dimensions of boxes with open top flap (LxWxH) | mm. | 1000x650x975 |

| Box Type (suitable in an automatic process) | ref. FEFCO | 0200 / 0201 |

| Grooves (corrugation) type | ref. GIFCO | A-B-C |

* Specifications may be subject to change.

GTA-OS OPPOSITE VERSION

If required the machine can be built in the opposite sided version.

GTA-SC COLOURS OUT OF THE STANDARD

On request

V-INOX STAINLESS STEEL

On request.

FX - PHOTOCELL FOR COMMITTED LINE

Device for automatic operation of carton former, with line overflow control, by intercepting cartons with photocell. The kit is completed by wired cable with quick-connect connector

MAG681-MAG610MOTORIZED WAREHOUSE

MAG681 – Motorized warehouse 1.3 m ~ 120/130 boxes (for GF608L)

MAG610 – Motorized warehouse 1.3 m ~ 120/130 boxes (for GF610L)

(*) Safety guards according to EEC standards included.

GT-EKR

REMOTE ASSISTANCE KIT

The remote service kit allows control of machine adjustment parameters in case of malfunction.It also allows for any software changes without the need for a technician to come out.