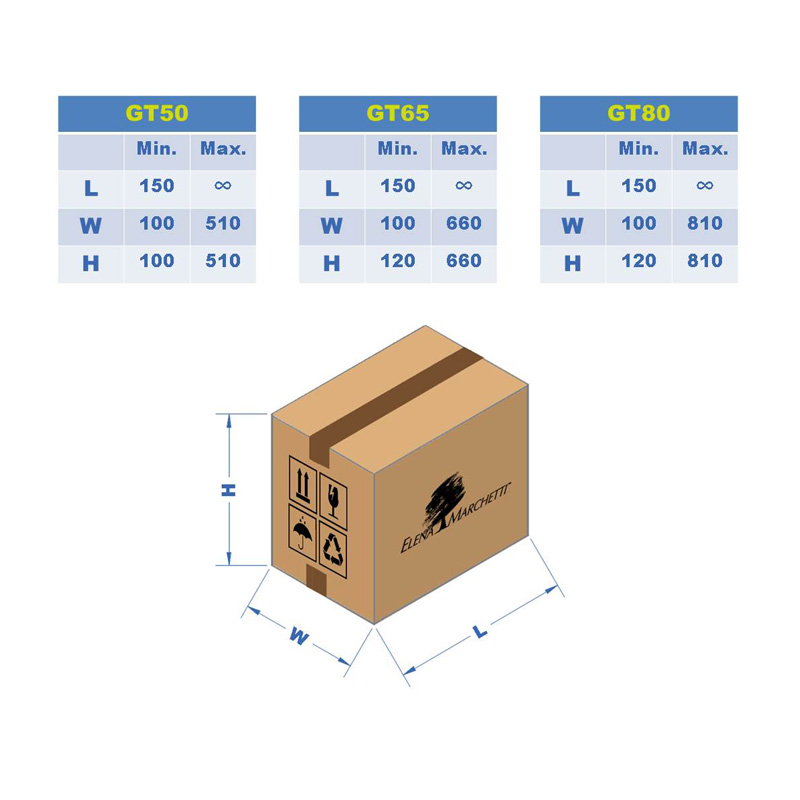

GOLDTAPE 50 – 65 – 80

Semiautomatic carton sealer with manual adjustment for top and bottom sealing of uniform American-type box size batches with adhesive tape

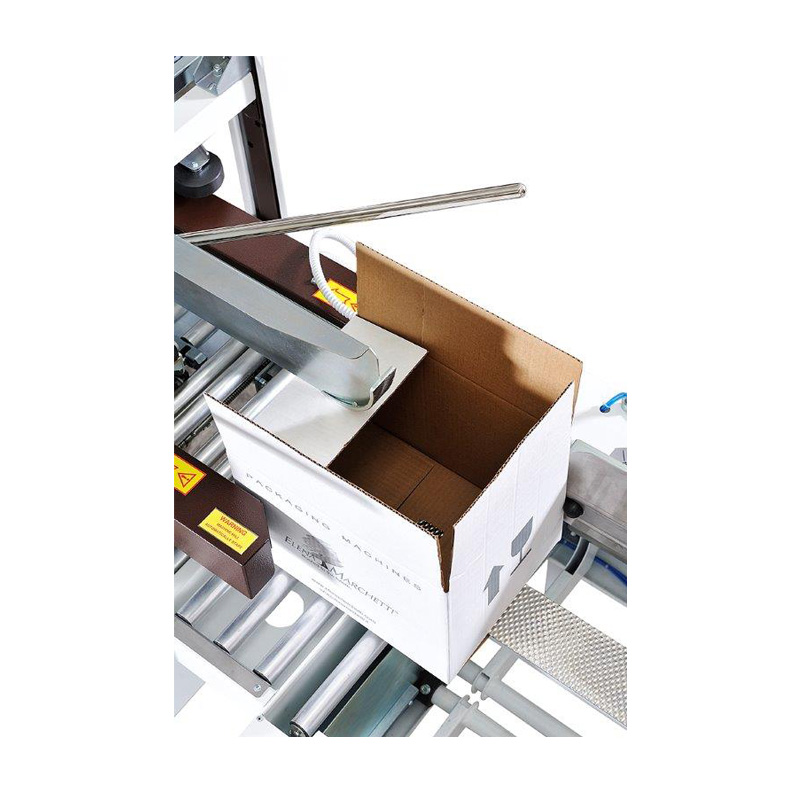

The machine can be used by unskilled operators as it requires very easy adjustment operations. The operator squares the boxes folding the bottom flaps, fills the boxes, folds the top flaps and insert them into the machine. While the boxes pass through the machine the top and bottom flaps will be sealed simultaneously by the taping heads. The boxes are fed by side belts, driven by a single motor ensuring a smooth carton transport. This solution grants a perfect uniform box sliding, aligning of the flaps and an optimum sealing, through the performant TU taping heads.

Combined with infeed and outfeed conveyors, represents a simple, fast and userfriendly packaging station.

- Machine table made of free metal rollers

- 2 columns frame, 1 with screw, to symmetrically move top taping head

- 4 side pressure rollers (2 + 2) to keep the box top flaps closed

- Special system to lock the top taping head frame in the upper position to facilitate bottom tape reel replacement

- 2 taping units (top & bottom), TU2 for 50mm tape (GT50) – TU3 for 75mm tape (GT65-GT80) / different on request

- Start & Stop button with Stop emergency button in ergonomic & easy to reach position

TECHNICAL DATA

GT50 |

||

| TECHNICAL DATA | U.M. | |

| Machine footprint (LxWxH) | mm. | 990x965x1420 |

| Machine weight | Kg. | 120 |

| Hourly production rate | Boxes/h | 1400 |

| Width driving belts | mm. | 65 |

| Timing belts speed | m/min. | 24 |

| Minimum box dimensions (LxWxH) | mm. | 150x100x100 |

| Maximum box dimensions (LxWxH) | mm. | ∞x510x510 |

| Maximum weight of the box | Kg. | 6 each 100 mm. length |

| Workbench height | mm. | 650 ÷ 750 |

| ELECTRICAL DATA | U.M. | |

| Voltage | V | 400 |

| Phases | n° | 3~+PE |

| Frequency | Hz | 50 |

| Installed power | kW | 0,22 |

| IP rating | IP | 54 |

GT 65 |

||

| TECHNICAL DATA | U.M. | |

| Machine footprint (LxWxH) | mm. | 990x1146x1544 |

| Machine weight | Kg. | 135 |

| Hourly production rate | Boxes/h | 1400 |

| Width driving belts | mm. | 90 |

| Timing belts speed | m/min. | 24 |

| Minimum box dimensions (LxWxH) | mm. | 150x100x120 |

| Maximum box dimensions (LxWxH) | mm. | ∞x660x660 |

| Maximum weight of the box | Kg. | 6 each 100 mm. length |

| Workbench height | mm. | 650 ÷ 750 |

| ELECTRICAL DATA | U.M. | |

| Voltage | V | 400 |

| Phases | n° | 3~+PE |

| Frequency | Hz | 50 |

| Installed power | kW | 0,22 |

| IP rating | IP | 54 |

GT 80 |

||

| TECHNICAL DATA | U.M. | |

| Machine footprint (LxWxH) | mm. | 990x1297x1694 |

| Machine weight | Kg. | 140 |

| Hourly production rate | Boxes/h | 1400 |

| Width driving belts | mm. | 90 |

| Timing belts speed | m/min. | 24 |

| Minimum box dimensions (LxWxH) | mm. | 150x100x120 |

| Maximum box dimensions (LxWxH) | mm. | ∞x810x810 |

| Maximum weight of the box | Kg. | 6 each 100 mm. length |

| Workbench height | mm. | 650 ÷ 750 |

| ELECTRICAL DATA | U.M. | |

| Voltage | V | 400 |

| Phases | n° | 3~+PE |

| Frequency | Hz | 50 |

| Installed power | kW | 0,22 |

| IP rating | IP | 54 |

* The specifications may be subject to change.

GTA-06

RFN TAPE BREAKAGE/END SIGNAL FOR 1 TAPING HEAD

RFN tape breakage/end signal 1 head.

GTA-07

RFN TAPE BREAKAGE/END SIGNAL FOR 2 HEADS

GTA-16

SET OF 4 TELESCOPIC LEGS WITH FIXED FOOD

Set of 4 telescopic legs with fixed foot, excursion 650/950 mm with ruler.

GTA-17

SET OF LEGS WITH CASTERS Ø 80 mm

Set of four support legs equipped with swivel wheels and brake. They allow fast movement and safe positioning of the machine.

GTA-18

SET OF 4 ADJUSTABLE LEGS WITH CASTERS Ø 100 mm

Set of 4 telescopic legs with casters Ø100 mm, excursion 650/950 mm with ruler.

GTA-11

STOP & GO

Timed stop of the belts (energy saving kit).

GTA-11/1

INCREASED SPEED OF THE BELTS

GTA-11/2

DECREASED SPEED OF BELTS

GTA-11/3

PROLONGED MOTORIZATIONS INFEED/OUTFEED

200 mm prolonged motorizations infeed/outfeed (attention could need a connecting roller conveyor).

GTA-11/4

LIFTED MOTORIZATIONS

Raising side motor position by 100 mm.

GTA-11/5

PROLONGED MOTORIZATIONS INFEED/OUTFEED

200 mm prolonged motorizations infeed/outfeed (attention could need a connecting roller conveyor).

GTA-11/6

INCREASED HEIGHT (H=90 mm)

RULL

Wide availability of pallets, roller conveyors and extenders to best handle box handling needs.