GOLDTAPE 34 – 346

Sealing machine with operator

Sealing machine with operator Box sealing with selfadhesive –tape

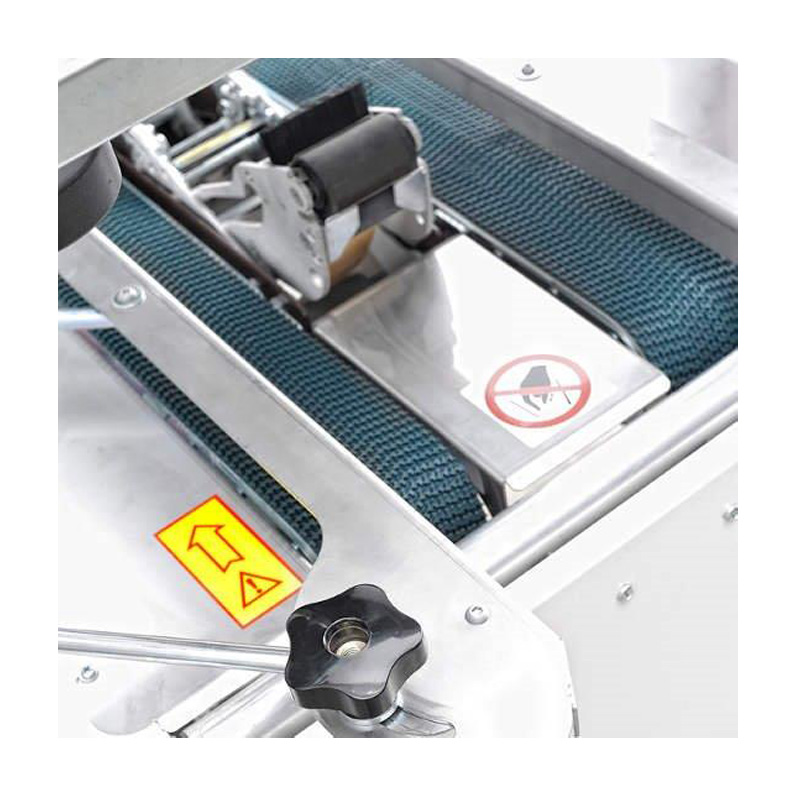

Box sealing with selfadhesive –tape Top and bottom belt drive system – top and bottom sealing

Top and bottom belt drive system – top and bottom sealing

Semi-automatic manual dimensioning tape sealing machine, with four flat bottom timing belts. The machine carries out, with auto-adhesive tape, the sealing of the bottom and top of same sized American type boxes.

This machine is particularly suitable for tall and short boxes. If combined with infeed and outfeed pack tables, represents a simple and efficient packaging station. The machine must be adjusted through handles on the box dimensions to be sealed. The operator squares the boxes folding the bottom flaps, fills the boxes, folds the top flaps and insert them into the machine. While the boxes pass through the machine the top and bottom flaps will be sealed simultaneously by the taping heads.

-

- Box transfer on driving belts combined with steel plates

- Two columns frame with one screw each to symmetrically move top taping head

- Safety protections according to the safety standards laws in force (CE certified)

- 4 side pressure rollers (2 + 2) to keep the box top flaps closed

- Self-centering bottom side guides to center the box in the middle of the machine

- 2 standard taping heads (top & bottom)TU2 for tape 50 mm wide (GT34), TU3 for tape 75 mm wide (GT346) from 25 to 50 mm. wide taping heads on request

- Start & Stop button with Stop emergency button in ergonomic & easy to reach position

TECHNICAL DATA

GT34 |

||

| TECHNICAL DATA | U.M. | |

| Machine footprint (LxWxH) | mm. | 990x1022x1464 |

| Machine weight | Kg. | 140 |

| Hourly production rate | Boxes/h | by the operator speed |

| Drag belt width (2+2) | mm. | 65 sup. / 90 inf. |

| Drag speed | m/min. | 24 |

| Minimum box dimensions (LxWxH) | mm. | 150x140x100 |

| Minimum box dimensions (LxWxH) | mm. | ∞x510x510 |

| Maximum box weight | Kg. | 6 per 100 mm. length |

| Workbench height | mm. | 650 ÷ 750 |

| ELECTRICAL CHARACTERISTICS | U.M. | |

| Supply voltage | V | 400 |

| Line phases | n° | 3~+PE |

| Power frequency | Hz | 50 |

| Installed power | kW | 0,22 |

| Electrical protection level | IP | 54 |

GT346 |

||

| TECHNICAL DATA | U.M. | |

| Machine footprint (LxWxH) | mm. | 990x1152x1614 |

| Machine weight | Kg. | 150 |

| Hourly production rate | Boxes/h | by the operator speed |

| Drag belt width (2+2) | mm. | 65 sup. / 90 inf. |

| Drag speed | m/min. | 24 |

| Minimum box dimensions (LxWxH) | mm. | 150x165x110 |

| Minimum box dimensions (LxWxH) | mm. | ∞x660x660 |

| Maximum box weight | Kg. | 6 per 100 mm. length |

| Workbench height | mm. | 650 ÷ 750 |

| ELECTRICAL CHARACTERISTICS | U.M. | |

| Supply voltage | V | 400 |

| Line phases | n° | 3~+PE |

| Power frequency | Hz | 50 |

| Installed power | kW | 0,22 |

| Electrical protection level | IP | 54 |

* Specifications may be subject to change.

GTA-OS

OPPOSITE VERSION

Upon request, the machine can be made with exactly mirrored layout.

GTA-SC

SPECIAL COLOR

On request

V-INOX

STAINLESS STEEL VERSION

On request.

GTA-SV

NON STANDARD VOLTAGE THREE-PHASE 400V-50Hz

On request

GTA-ULCSA

ULCSA VERSION.

GTA-SV

LOWER UNIT COMPARTMENT COVER

GTA-11/1

INCREASED SPEED OF DRIVE BELTS

GTA-11/2

DRAG BELT SPEED REDUCTION

RULL

RULLIER

Wide availability of pallets, roller conveyors and extenders to best handle box handling needs.